Teresa Cheng’s Caffeinated Mission to Decarbonize California Manufacturing

Electric roasting machines at Berkeley’s Bellwether Coffee. Photo: Christine Baker/Earthjustice

Teresa Cheng is helping electrify factories and food processing operations in California.

Along with the rest of the team at Industrious Labs, a company dedicated to decarbonizing the manufacturing industry, Cheng wants to help the state’s 35,000 mostly small- and medium-sized firms cut their carbon footprints. But as the organization’s California director, she’s also thinking about the possibility of creating thousands of high-quality jobs.

Cheng worked as a labor organizer for years before shifting to climate advocacy, and she’s interested in breaking down the perceived barriers between workers and environmentalists, with a larger goal of building widespread support for policy solutions. She envisions “a broad coalition” that includes climate organizations, environmental justice groups, labor groups, and businesses working to transform the state’s manufacturing sector in a way that tackles air quality and climate change head on and creates “a new industrial sector built on strong union labor.”

Industrious Labs recently hosted a tour of Bellwether Coffee, a Berkeley-based company that makes electric countertop coffee roasters. Bellwether has helped brands like Heirloom and Red Bay Coffee Company roast their own green coffee beans — which are more affordable than pre-roasted beans — all without using natural gas.

The goal of the tour was to showcase an example of decarbonization work in manufacturing, and highlight state policy solutions that can speed up the transition.

Berkeley’s Bellwether Coffee founder Ricardo Lopez leads a tour of his company’s electric coffee roasting machines. Photo: Christine Baker/Earthjustice

We spoke with Cheng about the tour, threats to industrial decarbonization under the Trump administration, and the path forward.

Q: Why is replacing gas appliances in factories with electric appliances important for the state to meet its climate goals?

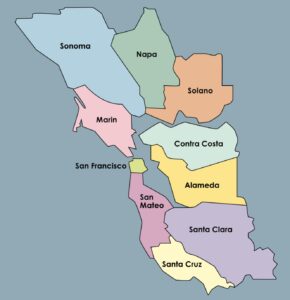

California has the biggest manufacturing sector in the entire country, and most folks don’t know that because we don’t have big aluminum smelters or giant steel mills. But we do have many firms producing products that we use every day — like coffee, which is why we did the tour at Bellwether Coffee.

We have tons of manufacturers making things like coffee and tea, cookies and crackers, medicine, deli meats, pulp, and paper. And manufacturers are a significant source of climate emissions and air pollution, in large part because of their reliance on burning gas. But many of them use low- to medium-temperature heat. A lot of it falls under 200 degrees Celsius (392 Fahrenheit), and there are commercially available technologies out there to replace gas heating equipment. We’re talking about industrial heat pumps to replace gas-fired boilers and water heaters, as well as thermal batteries and thermal energy storage.

These solutions are out there, and they’re gaining momentum. And we need to focus on deployment. What’s unique about Bellwether is that the early adopters of their equipment were also grantees from the California Energy Commission’s Food Production Investment Program (FPIP). That early funding allowed them to create a product that now is cost competitive with its gas-fired counterparts — which is incredible. Our state has one of the biggest differentials between electricity and gas prices, and even then, their [electric] product is more cost competitive for a cafe or restaurant to use instead of buying pre-roasted coffee beans.

We want all these manufacturing firms to stay in California, and we want them to clean up by making significant investments in their facilities [so they can] retain the more than 1 million people who work for them. And we want to create the kinds of good union jobs that are going to be necessary to build and install the new equipment, to do the duct work, and to retrofit these facilities.

Q: How does your labor background help shape this vision?

For years, I organized alongside hotel and restaurant workers. I was organizing mainly folks in the Bay Area, and I worked with Chinese, Southeast Asian, Ethiopian, Central American, Mexican, Black, and white working-class folks. It involved helping folks move past fear, division, and language barriers to work together and take on major employers. And it’s the perfect microcosm of what we need to do with the climate movement.

Q: How will the Trump administration’s shift away from decarbonization impact your work?

Under the U.S. Department of Energy’s Industrial Demonstrations Program, manufacturers received around $6.3 billion, and they raised more than double that in private funding (about $14 billion) for a number of groundbreaking industrial projects. Kraft had a program called Delicious Decarbonization that was going to decarbonize the heating at 10 different facilities. There was also a project at a Unilever ice cream factory, and one at Bulleit bourbon distillery in Kentucky. About two-thirds of the projects have had their funding completely clawed back, and we’re concerned that the few projects left could be targeted in the coming months.

Q: Can the state fill some of that gap for California companies?

In addition to FPIP, there’s another state effort called the INDIGO Program, which is also about deploying industrial technology. It put $68 million toward businesses looking to electrify in recent years, and it hasn’t all been spent yet. Industrious Labs and Earthjustice are co-sponsoring AB 1280, which is all about renewing incentives like those in the INDIGO Program. We feel like this is even more timely now that we see so much federal backsliding on other incentives. It was a one-time allocation, and it would be better for manufacturers if programs like this had continuous funding. We’re advocating for that through the Greenhouse Gas Reduction Fund.

Q: What’s the difference between home and industrial electrification, from a policy perspective?

The lines are more blurred than you would think. In both cases, it requires incentives, but we also know that it is going to take regulations to get manufacturers to switch their equipment. When you look at the rules local air districts are passing, they cover both commercial and industrial facilities. The same rules cover hospitals, schools, and chocolate manufacturers, and they’re all using the same industrial boilers. We’re part of a broad coalition of folks that is trying to advocate for updates to a rule at the Bay Area Air District that could establish a zero emission standard for industrial boilers. That would be the natural progression from the rule that will require homeowners to phase out gas-powered hot water heaters beginning in 2027.

Q: How would the policies on the table help support workers?

AB 1280 would renew and update project guidelines for the INDIGO program, and that means updating the labor standards. It would require grantees that receive public funding to have a project labor agreement, for instance. Since we’re creating this new economy, we want it to be based on strong labor standards.

Valero refinery in Benicia which plans to close soon. Photo: Baykeeper

Q: We know that residential electrification has happened on a piecemeal level, and that’s made it challenging for unions to get involved.

The refinery closures are top of mind here in the Bay Area. The oil and gas workers [fought for] great union jobs. And some of the trade groups have seen rules and policies [that require replacing gas appliances] as a threat. But there are some interesting opportunities when it comes to industrial heat, even beyond installing this new equipment and retrofitting these facilities — and that is the potential for geothermal and district heating to provide industrial heat.

We’ve used a mapping tool from Project Inner Space that maps out all the sites across the country with geothermal potential, and our analyst overlaid that with the industrial facilities that are covered by some of these air district rules that Industrious and other groups are trying to pass. There’s significant overlap. There are places where thermal energy networks tapping into geothermal or waste heat from other facilities could help directly decarbonize industrial facilities. We know that would also require a lot of piping — and that requires very skilled labor. In New York, there’s an interesting partnership between environmental justice and climate groups and the pipe fitter’s union. Together they have been able to jointly advocate for geothermal and district heating projects, which they see as a win-win.

But the gas industry is pushing back.

Yes, the gas companies have been on a campaign to try to stop these rules everywhere — from Southern California to New York. Clearly, they see the industrial and the manufacturing sector is one of their last stands. They really want to keep these folks on the gas system, even though the other sectors are moving away. (And if manufacturers don’t move off it, they’re going to be stuck footing the bill for the whole system.) The gas industry is taking very, very aggressive efforts to try to stop that from happening, because they know that as more manufacturers start to realize that these electric alternatives are superior products — they have greater precision control, for instance — that will be a death spiral for them. So, it doesn’t surprise us that they’re aggressively trying to hang on.

This interview was edited for length and clarity, and was originally produced by the Climate Equity Reporting Project at Berkeley Journalism.